Steel

Steel is the foundation of blade quality.

To appreciate a blade the steel structure is very important.

To recognize the steel quality is a little difficult for beginners, but

very interesting.

Japanese blades have a layer pattern caused by fold welding work. These

patterns are interesting and are one of the characteristics of the blade.

(layer pattern = HADA in Japanese)

However, this fold pattern has no bearing on steel quality.

A beautiful layer pattern does not necessarily mean good steel. It

is a secondary effect of the fold welding.

In Japanese blades this forge welding is not performed to create a patterned

steel. The pattern develops as a bi-product of refining the steel.

This is a very big point that many overseas collectors misunderstand.

Good blade steel, in other words, has a clear colour and is made of fine

particles. That comes from good material and good hardening (heat treatment).

Such a steel must accompany a good hamon. This doesn't mean an aesthetic

hamon pattern. It means a hamon that is bright and made of fine particles

(Nie/Nioi).

This is what the samurai of the past appreciated in a blade because behind

the beauty lay a weapon they could trust with their lives.

-important-

The main purpose of fold welding work is to refine the primitive steel.

The raw material for a Japanese blade is very pure, but primitive. It contains

slags and voids due to the low temperature reduction utilized by the traditional

Japanese smelting process.

Blade smiths squeeze the slag out of the steel by a fold welding method.

Finally, they arrive at a fine grained, pure steel block that can be used

for blades. This refining work put layers in the steel as a secondary effect.

When we try to attribute a blade to an individual smith, the layer pattern

becomes one of elements we use to define the smith's tradition or his personality.

In the modern age, people began to appreciate the layer pattern designs

as an art form.

However, what ever the layer pattern, it does not define steel quality.

Sometimes blade steels show open layers. These failed welds are detrimental

to the aesthetics of the blade but they don't necessarily mean a lack of

quality in the steel.

Likewise, a blade with no weld failures can't be guaranteed to have good

steel. ( => open layer)

Visible and attractive layer patterns do have visual appeal and I see nothing

wrong with this, as long as steel quality is maintained.

For example, Norishige is a master of the Soshu tradition who is famous

for a large designed layer pattern. Most of his blades are master pieces.

A layer pattern like Norishige's is easily produced by modern smiths, but

any layer design doesn't make the blade a master piece. The layer pattern

is just a copy of Norishige's style, his "Face", like a caricature

on a newspaper.

Norishige's blades are considered masterpieces because of his steel, which

is very active with particles running throughout the larger layer pattern.

Recognizing the particles of the steel is much more important

than the layer pattern and much more interesting. (particles of steel

= JINIE, in Japanese)

In other words, watch carefully the depth of colour, the brightness of

the steel and the activities of the particles on the surface. These are

the criterion for quality in hardened steel.

Good Japanese blades should have a white or sky-blue

colour in the hamon area, bright hamon line and clear, deep colour between

the hamon and the utsuri. (UTSURI = shadow of hamon)

I don't mean the colour made by the various polishing techniques. The true

colour can be seen in good reflected light. ( => HAMON )

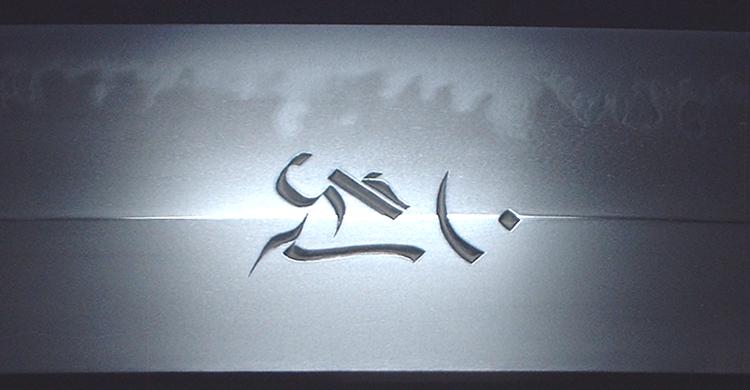

Frontal view of the steel.

A view using proper reflection. This is the same part of the above blade.

These two pictures are of the same pert of one blade.

The difference in views comes from the difference of lighting.

A deep colour of the steel

Material

TAMAHAGANE and OROSHIGANE

Traditional Japanese blades are made from a pure carbon steel that is produced

by the low temperature deoxidization method.

The steel is mainly TAMAHAGANE, with additions of OROSHIGANE.

TAMAHAGANE is made by the TATARA method from iron sands using plenty of

charcoal. It is a kind of bloomry steel. That is primitive, but very pure.

The smelt temperatures in the Tatara are low and the reduced iron doesn't

become fully liquid. Because of this, other trace elements in the sands

can't form alloys in the steel and are removed along with the slag.

A fresh born tamahagane billet from the tatara furnace is very big. It

is the size of a calf and includes various qualities of steel. It is broken

into many small pieces, and they are supplied to smiths.

Tamahagane is very pure as a steel. But it has some slags and many voids.

A fist size piece of TAMAHAGANE.

Pieces of tamahagane are not the same quality. Each of the pieces have

different quality. So smith checks the broken surfaces to know the quality.

The left is hard and dense, with a high carbon content. It is used for

the cutting edge steel. It can become sharp edge, but brittle.

The right is milder. Rough and lower in carbon content. It is suitable

for the back and body of the blade. It can become tough and flexible.

(NBTHK Tamahagane => たたら操業と日刀保たたら (touken.or.jp))

OROSHIGANE is a steel that made by sword smiths themselves. By this process

the smith gets exactly the quality of steel he wants. The materials of

Oroshigane are small pieces of Tamahagane, pure iron, sponge iron, electrolysis

iron and old iron wares that were made from Tatara smelted iron. Anyhow

eliminate non-Fe metals.

Using there own fires, and plenty of charcoal, the smiths can produce their

own pure carbon steels. Simply put, Oroshigane is a smith personal tamahagane.

(A fresh born OROSHIGANE)

The slags at the bottom of forge can be a material of Oroshigane. In the

work of forging Tamahagane, slags melt down at the bottom of the forge.

After the work, apprentices clean the forge and pick the slags up as their

treasure, because the slags can include some steel. They break the slags

and collect small pieces of steel. When they have collected enough amount

of steels, they can make Oroshigane using master's forge. They can get

good quality steel by their good work.

Then these steels are refined with the fold welding method.

(=> Definition of Iron, Steel,

and Cast Iron)

Home > Information, Blade > Steel

We have received questions from a customer.

----------------------------------

I read about Sunobe blades but i`m not sure...

you say "For modern steel, fold

welding work has no effect onto its quality."

My doubt is:

why for tamahagane fold welding

work has effect on to its quality ?

why for modern steel has NO effect

?

I post the question on http://forums.swordforum.com/showthread.php?t=90205

The problem is "simple" i think...a japanese smith does not know what happened with the steel, but know HOW TO MAKE nie-jifu... and a metallurgist know what happened with the steel but DOES NOT KNOW how to make nie-jifu... ( or the modern steel does not help him... ??? ... )

Everybody copy and paste the documentations...without understanding and

this is a big problem for nihonto knowledge, and this is the key point

( this miss-understanding ) a key-point who is used by fake-bladesmiths

to sale the blades for people ( unfortunately ).

I try to understand all two process to explain with " child words

" what is the differences between ancient making process and modern

process, the ancient steel and modern steel. For contemporary people is

impossible to be an ancient steel better than a modern steel, for this

reason modern steel blades is on top.

------------------------------

I will try to answer the questions here.

I will try to answer the questions here.

Tamahagane is a pure steel as meaning of metal. As the word in metallurgy,

"pure" may be not correct. Steel is an alloy of Iron and Carbon.

So it should say "a simple steel", because it doesn't include

other metals.

Tamahagane is a steel of purely Iron and Carbon at the part of metal. But

it includes some amount of slags and many voids like bubbles. And the carbon

content is not homogenized in parts. These characters are come from the

low temperature smelting.

So it is impossible to use tamahagane as just it is for blade.

Then smith takes the fold welding to refine it. By heating in the forge,

slags in tamahagane becomes melting. Pounding work squeezes the melting

slags out of the tamahagane block, and shuts the bubbles. Smith makes heating,

pounding, and folding again and again. Many times heating and pounding

squeezes slags well, and many times folding spreads the carbon content

evenly into the steel block as many layers. In the other hand, the carbon

is burned out by heating. So smith cares to control carbon content. In

other words, careless work of fold welding makes the steel too mild.

In conclusion, the fold welding work on tamahagane makes a good steel block

that can be used for blade. That is no slags, no bubbles, even carbon content,

and contains suitable amount of carbon.

This is the "effect" of the fold welding onto tamahagane.

On the modern steels.

There are various kinds of steels that are specially made for each usage.

A modern steel for edge tools is already contained many metals to get the

best utility to the target. The modern technology can make steels like

a mix metal juice by controlling all the metal contents, and formed into

various sizes of bars or plates. Of course, the steel never includes slag

nor bubbles. You can choose the best one out of various kinds of steels,

and instantly forge it to blades or other tools. Modern steels are already

completed special alloys.

If you take fold welding onto such modern steels, the heating work doesn't

effect the content of the metals. Only carbon content can be down. I am

afraid if the best balance of contains are broken by the work. And the

fold welding work can put the oxidized iron among the layers of steel.

In conclusion, the fold welding work onto the modern steels can get down

the steel quality, rather than "no effect".

In the meaning of utility tools, modern steels are better than tamahagane

to make good blade. You can select several kinds of steels for each part

of blade, and construct a blade with them.

The policy of steel making by Japanese sword smith is opposite to the modern

technology. The modern technology tries to find a best balance of steel

contains. But Japanese sword smith tries to get a simple steel as possible.