Flaws of blades

To study the flaws of blades is not enjoyable.

But to know the meaning of the flaws is useful to recognize

the quality of blades.

Many books explain about the flaws of blades how they

are found, but they do not explain how serious they are.

Now let's study about the flaws how bad they are for

the quality of blades.

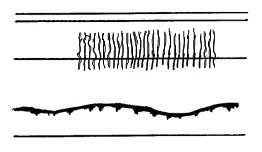

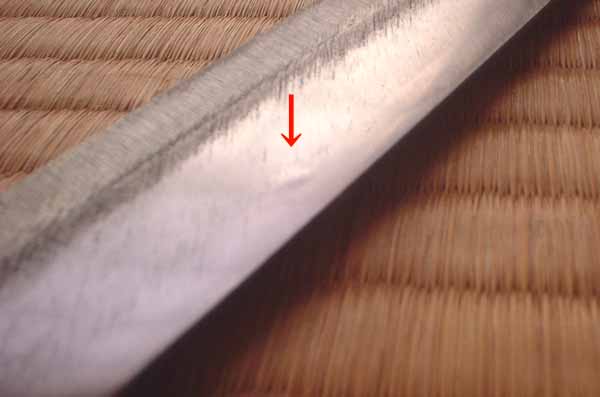

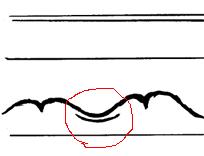

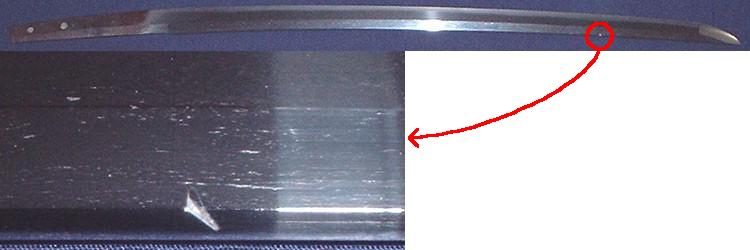

Open layer (kitae-ware,

in Japanese)

This kind of flaw is the easiest to be found. It is not good for its visibility.

But in most cases, it is not so serious as it looks like. It is only a

trouble for eyes.

A small flaw from fold welding work does not make the quality of the steel

down. No kitae-ware does not mean good steel. We have to see the colour

and brightness of the steel (in other words, the condition of the steel

particles) to know its quality.

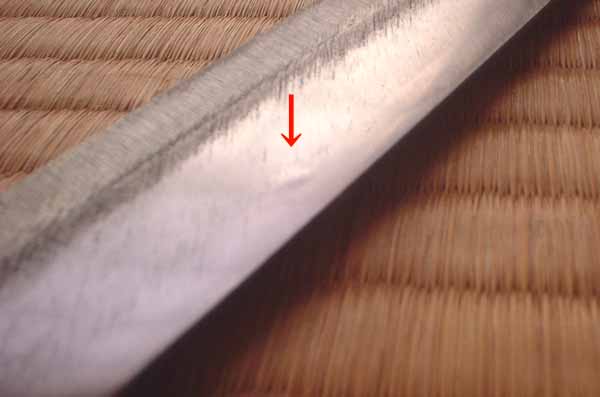

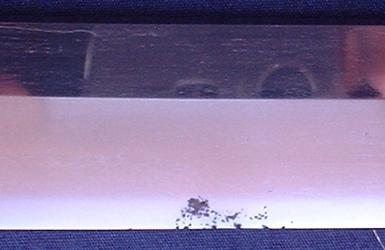

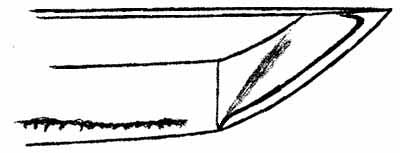

Sometimes, a thin open layer becomes a blister (fukure in Japanese). Unfortunately

it looks so bad for eye. It is a pitiful flaw.

A blister in a newly forged blade.

A blister on an old blade.

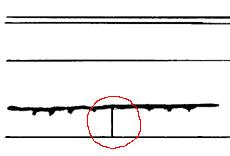

Rusty dimple (kuchikomi)

Sometimes deep rust leaves a dimple on blade, even after a completed polishing

work. It is bad for beauty of the blade.

But a healthy blade with some small dimples is far better than a poorly

shaped blade. A careless grinding to remove deep rust is the worst way

of work. We have to keep the full meat on blade surface.

In old days, sometimes such a dimple was filled with red lacquer to stop

rusting.

Of course the rust in the dimple has to be cleaned before

the lacquer work.

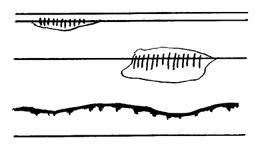

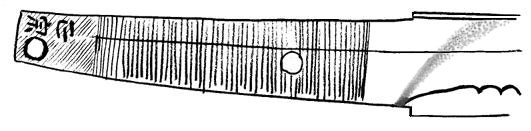

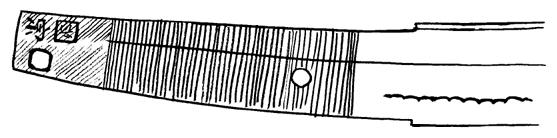

Patched steel (umegane)

A different steel is patched into blade surface like a small inlay.

It includes a serious problem. Because it does not come from any failure.

It is produced by dishonest will.

When there is some open layer or rusty dimple on a blade, some kind of people want to mask it. Then he carves a ditch bigger than the opening or the dimple on it, and patches other steel into the ditch and strangles them to make good fit.

This does not fix the flaw. In fact, the steel is damaged by spreading

the flaw. Rust is growing at the bottom of the patched steel. After some

times of polishing the patched steel will be taken off and a large hole

is left.

The work in old days is simple with rectangular patch.

Recent work is worse, because the patch is done according with the layer

pattern. Such work is done to trick beginners' eye. A skilful work makes

it difficult to be disclosed.

Be careful, because some books introduce this method as a way to repair flaws. Serious sword lovers never like such tricks.

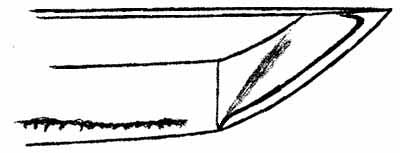

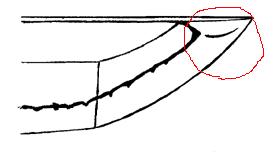

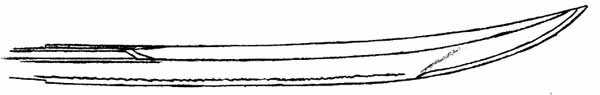

Cracks in hamon (yaki-ware)

This kind of flaw is most terrible. Some of them are really bad. It is

a little difficult to be found. It is thinner than a hair line, but sharp

and deep. This crack appears in the hamon area by a mistake in hardening

work.

It has some different types. (Do not confuse open layers in the hamon area to cracks.)

This type is most terrible.

(=> Episodes by Kokaji, tempering crack)

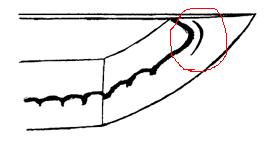

This type is specially called "hagire".

This type of crack does not come only from the hardening failure, sometimes

a hard back attack can make such a crack too. I don't know why, but hagire is most hated in all kinds of flaws at market. In fact, it is not the most terrible flaw in all kinds of them.

In the current market, collectors don't mind cracks in hamon seriously

except for hagire. I have seen some number of Juyo blades that had serious cracks in hamon. "Juyo" is a title that

is authorized by NBTHK. They connived the cracks.

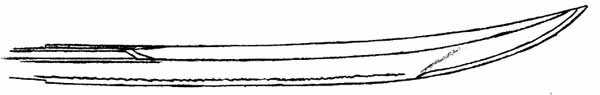

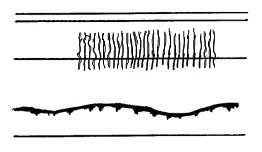

Poor steel, Steel cracks (shinae)

It is a steel including much of slag, rough welding.

The worst is a steel that has cracks by itself. The steel is not strong.

We call such cracks "shinae" in Japanese.

Cracks on the blade surface.

Cracks on the back surface.

On the other hand, there is a similar appearance called

"mukade-shinae". It appears in blade surface like wrinkles, not

cracks.

It is not a flaw. When a blade is heavily bent and straighten again, it

appears on the blade surface. It is very thin wrinkles on the steel surface,

so it can be removed by sometimes polishing.

Poor hamon, No hamon

A dark hamon means a mild cutting edge.

But too hard cutting edge is not good. Such a hamon looks

like a mirror.

To see the brightness of hamon area is important.

When a blade meets an fire accident, the hamon disappears by burning out.

(=> HAMON)

(=> A sword in fire

accident)

On some old blades, the hamon is vanishing near the tang

as original. It is not a problem at all.

Fake hamon

Some polishers forge a fake hamon on blade that has no hamon.

Some of them are so skilful that is difficult to discover the trick by

a beginners eye.

Some is a part of hamon, and some is all the hamon. (=> fake hamon)

Being weary (tsukare)

The shape has been broken by much grinding.

Sometimes the hamon was worn out by too much grinding.

Re-hardening (yaki-naoshi, saiha)

When a blade has been burned out by the fire, it is hardened again to recall

its utility. But the originality of the blade never come again. So the

value as a piece of art disappears, even if the blade has a good signature.

It is difficult to recognize if the blade was re-hardened or not, only

by looking at the blade surface. To research both the tang and the blade

is necessary to think about it.

Next is an example of the case of a shortened blade.

If the signature is genuine, this starting of hamon means re-hardening.

The vanishing of hamon toward the tang is correct. This blade was not re-hardened.

Step-hardening (yaki-tsugi)

It is a kind of re-hardening.

Kissaki is most frequenly damaged area in a fight. So some blades are worn

out there. Sometimes such blades are re-hardened only around the kissaki.

But the new hamon never connect to the original hamon. Some part before

the new hamon is burned out by the heat of the hardening work. So, good(?)

polishing is necessary to mask the inefficient part.

The new hamon must be followed with mizukage at the start of it.

(=> Episodes by Kokaji, step hardening)

Fake signature (gimei), counterfeit

A signature put on the different blade. It was purposed to deceive collectors.

Do not be enticed by the signature. The quality of the blade is most important.

Un-original engraving (ato-bori)

If it accords with the blade, it is not so bad. We can not find any problem

on it.

In old days, engravings were added on blades for prayer. On old blades,

it is not easy to find if the engraving would be done originally or later.

But recently it was occasionally done to mask flaws. Such a work that break

blades is so bad.

An open layer is far better than a terrible dragon.

These two Sanskrit-like letters are so bad. The worth of the blade disappeared

forever.

-Do not restore an original engraving-

Some engravings in old blades have been partially erased by much polishing.

I wonder if you would like to restore it by some craftsman. But please

never touch the original engravings. Engraving is not only a decoration

putting on the blade. It is a prayer of samurai old days. You should respect

original engravings even though it is erasing.

-Examples-

Suken by Kuniyoshi: the centre line of suken has worn out.

Kurikara by Kagemasa: the dragon has worn away in some parts.

Broken cutting edge (ha-kobore)

A small nick on the cutting edge is not a big problem,

to keep a good shape is more important.

Notches by battle (kirikomi)

It should be called a pride rather than a flaw.

This cutting mark still has the enemy's edge bitten off.

It came from an old day's sword fight.

Home > Information, Blade > Flaws