And the real Soshu tradition blades are the same.

Three-layer styles = SAM'MAI, HON-SAM'MAI, and SHIHO-ZUME

It is made by a sandwich-like method.

On the cutting surface, the border of the two steels appears. Sometimes this border makes a visible effect into the hamon.

Examples - tanto by the HASEBE school

- Gassan blades (=> Tanto mumei Gassan)

- some of MINO blades

- some blades made by KIYOMARO

- some blades made by SYOHEI MIYAIRI

We don't know why, but many of Soshu style blades in the modern age are made of this construction. The genuine Soshu blades are the wrapping style, but some of the copies of them are made of the sandwich style.

3) Three-layer = SAM'MAI

In this case the core steel is harder than the outer steel. (=> Chinese double edged blade)

4) HON-SAM'MAI

c = core steel

o = outer steel

e = cutting edge steel

In this case there is one more, a third kind of steel - the cutting edge steel which is the hardest of all.

The core steel is the mildest.

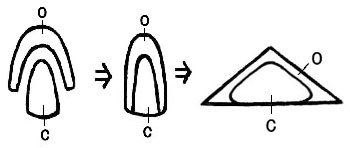

5) All directions packing = SHIHO-ZUME

c = core steel

o = outer steel

e = cutting edge steel

b = back steel

This type of construction is made of four kinds of steel: the core, the outer, the cutting edge, and the back steel. The hardest is again the cutting edge steel, the mildest is the core steel.

6) Reverse wrapping = GYAKU-KOBUSE

In this case the core steel is harder than the outer steel.

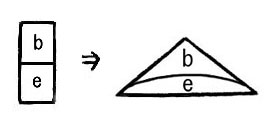

7) Two-block = HYOSHIGI

This type is typical for the YAMATO tradition blades. (Yamato is a name of one of the provinces in Japan)

b = back steel

e = cutting edge steel

This type is made of two kinds of steel - the back steel and the cutting edge steel. (an example: tanto "Naohiro")

The percentage rate of these two steels can be 2:1, 1:1, 1:2, and any.

Others

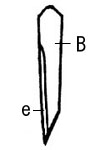

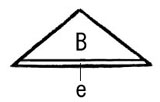

8) Putting = HARI-HAGANE

B = body steel

This type can be used for Kata-kiriha-zukuri blades. (an example: tanto "Naohiro" in Kata-Kiriha)

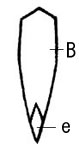

9) Inlaying = WARI-HAGANE

We have received a question about steel constructions for Hira-sankaku-zukuri.

KOBUSE

Two-block

(an example: yari "Naohiro")

(an example: yari "Naohiro")HARI-HAGANE

More information regarding the steel construction, => "What is Shingane?"